This is part 1 of series "Kona EV Conversion":

- Salvaging a Kona (this post)

- Dismantling the Kona

- Kona CAN Decoding

- The motor turns (too much)

- Unremarkable Kona Progress

Electric Vehicle Conversion: Part One

At the end of Part Zero I had vague but ambitious goals to convert a diesel Peugeot 406 into an electric vehicle. Most of the necessary parts were collected, apart from a high voltage battery. This plan got scrapped! What happened?

I bought this 2019 Hyundai Kona Electric Highlander at a salvage auction. It wasn't planned, but some of these have sold at auction pretty cheap so I sat in on one of the auctions "just in case". Oops!

Can we fix it?

This Kona is technically a "repairable write-off", meaning that it's possible for it to be repaired and re-registered in Australia if a particular process is followed. This is unlike a "statutory write-off" which can never go back on the road here. Repairing seemed viable, until it turned out there was a bent chassis member in addition to the panel damage and blown airbags/pre-tensioners.1 A whole front section would need to be cut out and new metal re-welded according to the manufacturer's procedure. Finding someone to do that kind of repair on a modern vehicle is apparently difficult.

On top of that, access to the Hyundai repair database was suddenly blocked last July, ironically because Australia now has the "Right to Repair". These two factors effectively closed the door on getting this car repaired to the necessary standard.

That's a bit sad, as repairing would have meant less waste: there are a lot of bits that won't find a new home in any conversion. I'm "wrecking" the car and I'll try to find new homes for all the parts I don't keep, but there's going to be a lot of random plastics and metals that no one will ever want.

Will it burn?

Hyundai Konas of this age have an unfortunate reputation for spontaneously catching fire...

(Image credit: Inside EVs.)

(Image credit: Inside EVs.)

In 2020 Hyundai issued a recall to perform a BMS software update, which didn't solve the problem. Eventually they figured out the issue was inside the battery's pouch cells. In 2021 a second recall replaced affected battery packs.

Had this Kona been recalled before it crashed? Before bidding I had entered the VIN in Hyundai Australia's recall search which returned no outstanding recalls. After winning the auction I got cold feet ("what if the write-off process removed the VIN from their database!?") and called Hyundai Australia. They confirmed over the phone that the battery recall had been done on this car, the date it was done, and the name of the dealer that did it. They couldn't tell me if the battery had been replaced or only inspected, but they could put me in touch with the dealer to ask this. Good enough for me!

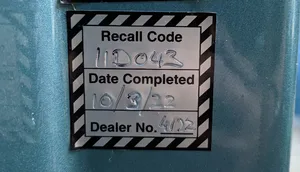

Later on, the BMS diagnostic interface showed that the battery pack had only completed about six full discharge cycles! I now know the factory date label on the battery pack is November 2021, the recall sticker shows the recall (code 11D043) was completed in March 2022, and then this car was crashed around April or May. So the whole pack is very new.

What to do?

The 64kWh battery pack in the Kona is way too heavy for the Peugeot I had planned to convert. The pack weighs 445kg, which is more than the entire weight allowance calculated in Part Zero. However, I had originally wanted to convert a ute. At the time I didn't think I could afford enough batteries, but this is probably enough batteries!

It should be possible to use most of the powertrain components from the Kona in a conversion together. This is very tempting because of all the factory engineering effort, thermal management, fault handling, etc. that has been put into this system. The barrier is that no one outside the Hyundai Kia Motor Company (HKMC) and their contract OEMs has documented exactly how these systems interact.

These are the modules I'd like to reuse. They are all connected to the Kona's Powertrain CAN bus ("PCAN"). Most of them are physically integrated on the "motor stack" in the engine bay:

- Vehicle Control Unit & Motor Control Unit (VCU & MCU). VCU receives inputs like accelerator pedal position and "gear" selection, and outputs motor torque requests to the MCU. MCU is the inverter that's responsible for actually driving the large electric motor. In a Kona these two modules are on the same PCB inside a box called the Electronic Powertrain Control Unit (EPCU). Link to a teardown.

- Battery Management (BMS). This will be little fiddly to repurpose as the Kona's large single battery pack will probably need splitting into two or three battery boxes in a conversion, but hopefully it is feasible.

- Smart Key Control Module (SMK). This will probably be needed as it tells the EPCU to disable the immobiliser. It communicates via CAN and some dedicated lines to the VCU. If necessarily, I'll mount it out of the way with one of the "smart keys" gaffer taped to it. If very lucky then there will be a way to make the motor turn without this unit.

- Onboard Charger (OBC). This includes the "DC/DC Converter" that charges the 12V system. This is incorporated in the "motor stack" on top of the electric motor and the EPCU.

- Charge Connector Door Module.

- Electric Water Pumps (EWPs). There are two of these. Very fancy: they're each a node on the CAN bus!

- A/C Control Module (FATC), depending on what is needed to make the active battery cooling work.

There are other modules connected to the PCAN bus that probably won't go in a conversion but may need spoofed/interpreted messages to keep everything happy:

- Active Air Flap (AAF). This sits behind the front bumper and controls a louvre to duct air through the radiator.

- Body Control Module (BCM). A common component in modern vehicles, the BCM is responsible for "body" functions like opening doors or switching on and off vehicle lights.

- Charge Control Module (CCM). I think this is actually for the Wireless Phone Charging system. However there is also apparently a small module somewhere that translates CAN messages to the PLC "ethernet over powerline" messages used in CCS2 DC Fast Charging.

- Airbag Control Module (ACM). The ECU that controls the airbags and other SRS systems.

- Brake Unit. Seems to be called both IMEB or iBAU (Integrated Brake Assist Unit) in different places. This is a single unit that includes ABS anti-lock brake system, electronic brake booster, and traction control. Among other things it sends CAN messages with data about vehicle wheel speeds.

- Dual Automatic Temperature Control (DATC). Probably talks to the other A/C control module.

- Vehicle Engine Sound System (VESS). This is the speaker that plays "engine sound" at low speeds. Some folks have reverse engineered these quite a bit already (see here, and here for example).

All together it's quite a lot!

Finding a way in

When the Kona arrived, I was happy that unlike the Outlander it was driveable already (possibly the salvage folks had been driving it around their yard!) Someone had even electrical taped the engine bay safety interlock back together after it would have been cut by the emergency first responders:

The first task was to get some logs from all the CAN buses. My friend @brainstorm, another Kona enthusiast, came out out help and we got stuck in.

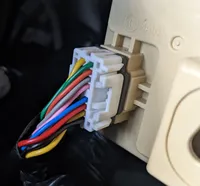

Unlike the Outlander, there's no simple access point for all Kona CAN buses. The best point seemed to be this connector "G" on the back of the main IGPM (Integrated Gateway Power Module), under the dash:

IGPM Socket "G" Pinout

| Pin | Function |

|---|---|

| 1 | PCAN Low |

| 2 | PCAN High |

| 3 | DCAN Low |

| 4 | DCAN High |

| 5 | BCAN Low |

| 6 | BCAN High |

| 7 | MCAN High |

| 8 | MCAN Low |

| 9 | Charging Connector Lock/Unlock Sensor |

| 10 | Hazard Light Switch |

| 11 | IG3 Relay Control |

| 12 | CCAN Low |

| 13 | CCAN High |

| 14 | Charging Connector Lock/Unlock Drive |

| 15 | Lock Relay |

| 16 | Alarm Horn Relay |

Vehicle tracker

Fortunately, my Kona came with an optional telemetry feature "AutoLink Premium", which provides a cellular interface to a GPS tracker and some of the car's functions.

Questionable security implications aside, this module plugs into two things: the OBD2 diagnostic socket, and a "Y cable" that splits out some signals from the same "Socket G" on the back of the IGPM:

As far as I can tell this is an Australia-only option, the cable and module don't even seem to have Hyundai part numbers.3 In other markets HKMC sells a similar vehicle telemetry feature but that seems to be integrated via the head unit(?) Not sure about this, please leave a comment if you know more.

The Y-cable doesn't intercept all the CAN buses, but could it be modified to do that?

Connector misery

Unfortunately while buzzing out the connector on the cable I made the foolish decision to "forward probe" the female plug with my fine-pitched multimeter probes, inserting the multimeter probes directly into the connector. Let the record show that @brainstorm warned me that I might damage it, and I said something like "nah these probes are really fine and we'll be gentle".

A little while later, the car didn't work at all - dozens of warning lights on the dash, refusing to go into "Ready" and become driveable.

At the time we didn't realise what had happened, we'd been probing and dismantling in a bunch of places but nothing that seemed like it could totally brick the car! Finding the root cause took some panicked troubleshooting as the plug still looked fine. I even dismantled the IGPM to check for internal damage:

Finally tried taking out the Y-cable, which unbricked the car and made it drive again. Phew!

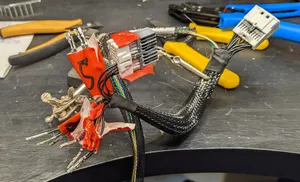

There still wasn't a better option to access the CAN buses, so I set about repairing the damaged plug (KUM part HK115-16011). This went badly! Re-seating the pins in the shell of the plug was a real pain: you have to do them all at once, the shell locks around them in a multi-stage process. It's probably simple in the factory with the correct tool or jig, but doing it on a bench with generic tools was pure misery.

Of course the OEM who makes these connectors2 doesn't sell anything to the public, but Taobao had a listing that looked like correct "TK105" replacement pins, price AU$0.13 each. Possibly leftovers from the factory where this Y-cable was made!

The pins turned up, and... still no luck! I couldn't do a good job crimping them with any of my generic crimping tools, plus the connector shell was starting to show wear from the number of times I'd taken it apart already.

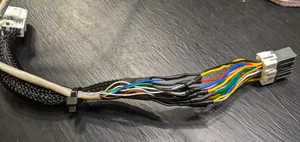

In the end I emailed EV Breakers in the UK and bought a new plug, cut from the loom of another Kona. Some cutting, soldering, and heatshrinking later and there was a custom Y-cable:

The cable has been rebuilt to break out all four main CAN buses, which split off to a length of CAT5 cable. This terminates in an RJ45 plug with this nifty screw terminal adaptor:

Finally, CAN logging could begin!

Second Kona!

By now I was not alone suffering the "Kona Virus". My friend Oli, who lives nearby, had somehow watched me struggle along and thought "I want some of that!". Oli has a farm ute EV conversion under his belt already, with ambitious plans for his next one. He managed to pick up a statutory write-off 2021 Kona for a bargain price:

We went and collected it from Melbourne in his 1974 Toyota Dyna, and it was delivered to its new home via some scenic back roads:

As the high voltage systems appeared totally unscathed, we decided to stop off at a local DC fast charger and CAN log a short charging session:

I'm excited to do this project with other people, it makes things a lot more interesting. Not to mention we can get more done as a group! As of last week we now have a third salvage Kona in the region, hoping to donate parts to a conversion!

I hope that I haven't started some kind of weird Hyundai wrecking cult...

CAN Logs

CAN logs from both vehicles are here on GitHub for anyone to take a look at, along with some notes about what was happening in each log.

I'm still finding my feet decoding these, but gradually making progress. Will post more about that soon.

-

I think the insurance assessor may have missed this as well, at least my novice understanding of the assessment criteria is that this extra damage should have made it a statutory write-off. ↩

-

Korean Company KUM, nowadays a division of Aptiv. ↩

-

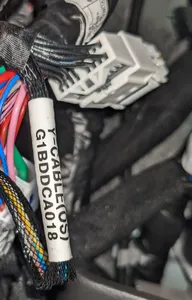

The OEM part numbers are visible on the devices: G1BDDMN015 and G1BDDCA018. These also didn't come up with much on the web (until now!) ↩

Thoughts on “Salvaging a Kona”